The 105-ton GENMA Mobile Harbor Crane (MHC), designed and built by Rainbow Heavy Machineries (RHM) for an overseas client, has been in smooth operation for nearly a year since its deployment in August last year. Its outstanding performance and comfortable driving experience have earned high praise from the client.

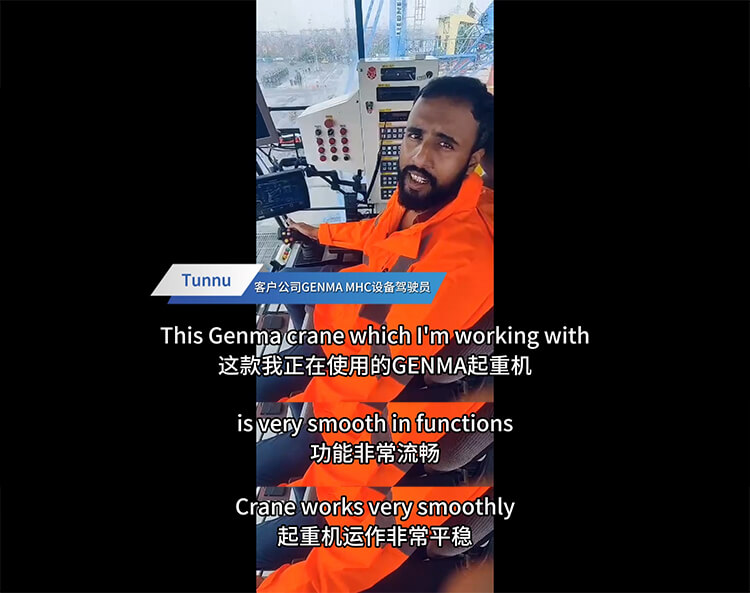

Mr. Tunnu, the operator of the GENMA MHC at the client company, said, "This GENMA crane which I'm working with performs functions very smoothly, and the operation process is very stable."

To meet the client's needs for loading and unloading containers, bulk cargo, and general cargo, the GENMA MHC is equipped with various work attachments such as hooks, grabs, and container spreaders, along with advanced intelligent management and control systems to enhance its functionality and performance.

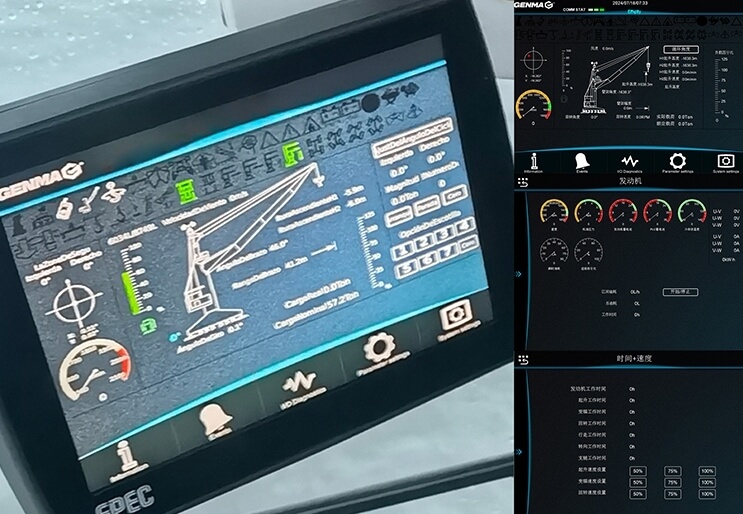

Intelligent Management Systems Ensure Stable Operation of the Equipment

Intelligent Power Adjustment System: The lifting, luffing, and slewing mechanisms of the GENMA MHC can intelligently adjust acceleration and deceleration based on the lifting weight and boom reach, ensuring smooth and safe operation.

Intelligent Diesel Management System: It can make real-time adjustments based on fuel consumption, ensuring continuous and stable engine power of the equipment while optimizing fuel efficiency.

Multi-Mechanism Linkage Intelligent Management System: Through intelligent linkage, the stable operation of each mechanism and sufficient power during the lifting process are guaranteed, improving operation efficiency.

Intelligent Control Systems Ensure Safe Operation of the Equipment

Intelligent Torque Limiting System: It can meet the crane's operational needs under various working conditions and with different lifting attachments, ensuring efficient and safe operation.

Intelligent Anti-Collision System: During the slewing and luffing process, the GENMA MHC uses integrated design and algorithms to achieve deceleration and stopping within a limited working area, intelligently avoiding collisions with other buildings or equipment, thus enhancing operational safety.

Crane Information Intelligent Management System: The operator can read real-time data on the working hours, pressure, current, alarm information, and historical records of each mechanism of the GENMA MHC, providing strong data support for managing the equipment's operational status.

Additionally, the user-friendly driver's cabin of the GENMA MHC is highly appreciated by the client. "The operator seat of the GENMA MHC is very comfortable, and the excellent visibility from the driver's cabin is highly functional. Working with the crane is easy and fast."

GENMA boasts extensive experience in MHC product design and manufacturing. It has independently developed some intelligent technologies, such as the intelligent path planning system, intelligent anti-sway system, and intelligent energy storage management, effectively enhancing the stability, environmental protection performance, and safety of the equipment, and providing clients with professional solutions for lifting operation and bulk cargo handling.