On March 28, the 6th China Manufacturing Power Forum was held in Baoding, Hebei Province. At the forum, new development concepts such as "innovation-driven", "intelligent manufacturing" and "green development" were mentioned several times, revealing the new direction of China's industrial development in the future and emphasizing the The strategic idea of transforming the old and new industrial dynamics of the manufacturing industry to achieve high-quality development in reform and innovation.

As an enterprise whose main business is high-end equipment business, Nantong Runbang Heavy Machinery Co. Under the guidance of the National 14th Five-Year Plan and the 2035 Vision, a series of operational and precise initiatives have been implemented for the intelligent and green development of the company's high-end equipment products.

● Driving product intelligence and innovating new momentum for development

Runbest Heavy Machinery's own brand - GENMA, focused on providing the market with high-quality lifting equipment and port machinery and other types of equipment, GENMA brand adhere to breakthrough innovation in the field of technology, so that products are more intelligent and better serve customers.

GENMA mobile harbour cranes (MHC), spread across a variety of integrated terminals such as container, bulk and multipurpose, can load and unload a wide range of cargoes such as containers, LNG tanks, general cargo and bulk materials, and are suitable for a variety of vessel types from barges to super-panamaxes.

The series of products are equipped with a number of intelligent technologies to achieve safe operation and maximise efficiency of the equipment.

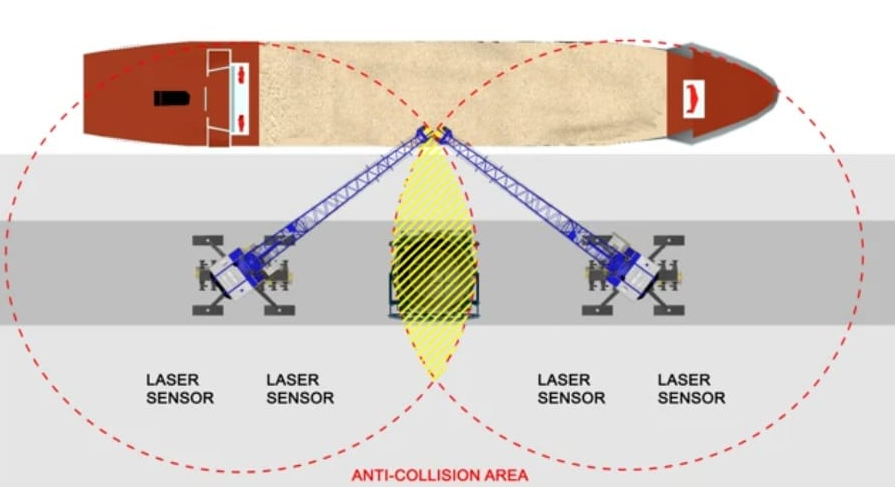

1. MHC Multi-Machine Intelligent and Reliable Collision Avoidance Warning System

During the joint operation of multiple MHCs, the magnitude of the collision avoidance wall is calculated and when the front-end sensor of the boom detects an object entering the collision avoidance area, the signal is fed back to the control system of the main engine in time, and the control system gives a signal to trigger its sound and light alarm device to enter the alarm state.

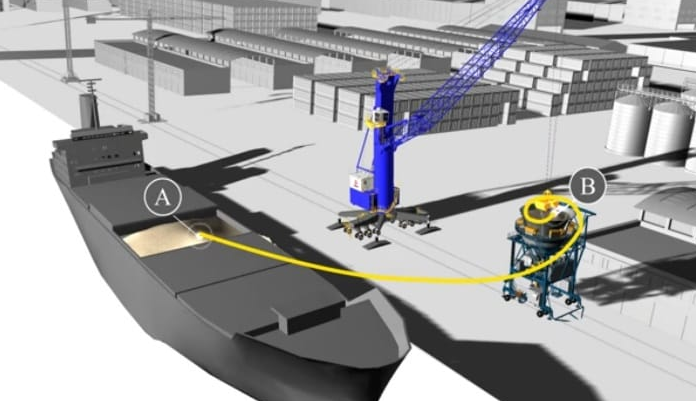

2. Intelligent path planning system and adaptive control function

The adaptive intelligent control function of the GENMA MHC grab can be controlled automatically for different magnitudes of goods with different densities, which can be selected flexibly to ensure maximum gripping capacity. The finished goods will be loaded and unloaded according to the optimal path, effectively improving work efficiency and reducing the driver's labour intensity.

3. Intelligent anti-sway system

On conventional jib cranes, swaying is inevitable. Through years of repeated testing, GENMA developers have developed the GILU intelligent anti-swaying system, which enables rapid sway reduction through the optimisation of the inertia model during cargo operation, thus improving operational stability and container loading and unloading efficiency. It effectively improves the efficiency and safety of work on site.

4. Intelligent energy storage management

The GENMA MHC automatically recovers and stores the potential energy generated when the crane is lowered, thus creating a hydraulic energy storage system. This system has been developed to redefine the energy consumption of the machine and the energy efficiency of the system. Automatic potential energy conversion into hydraulic energy, automatic determination of the amount of energy recovered and automatic return of the absorbed energy. This makes the machine the ultimate in energy use and power consumption, reduces the engine emissions per unit of time, and is intelligent and environmentally friendly at the same time.

● Deepening energy saving and emission reduction to promote green development

The GENMA brand ship unloader uses leading energy saving and environmental protection technology to effectively solve the problems of energy loss and dust pollution during operation and operation, and is suitable for all kinds of bulk materials, as well as power plants, feed mills and the aluminium industry.

1. Leading fan energy-saving technology

Unlike other Roots fan technologies, GENMA's multi-stage turbine fan technology solves the problems of high energy consumption and noise associated with traditional pneumatic ship unloaders. Compared to conventional pneumatic ship unloaders, GENMA ship unloaders can save up to 30% of energy while maintaining ship unloading efficiency.

2.Self-invented dust removal and environmental protection technology

GENMA grain unloaders use dust removal technology with independent intellectual property rights, using a new dust suppression hopper, so that the equipment can automatically adapt to the incoming material flow during operation, effectively forming a material column, perfectly solving the painful point of dust spillage. During the operation of the equipment, the national environmental control standards are strictly adhered to, in line with the requirements of green port construction.

In recent years, the "intelligent manufacturing equipment industry" has received great attention from the state and the industry. As an international high-end equipment provider, RHM insists on implementing the spirit of the two sessions, taking the new road of intelligent and green development, and creating a new situation of high-quality industrial development. The transformation and upgrading of "Made in China" to "Created in China".